Head of the Department of Physics and Space Science

Dr Luc Lévesque joined the Department of Physics and Space Science at RMC in July of 2005.

Dr Lévesque is a member of staff since July 2005. His work is related to infrared optics. Here are his main topics of interests. Each topic mentioned is divided in related sub-topics.

1. Laser-matter interaction

1a. Material spectroscopy in the near or mid-infrared

Infrared lasers can be used to characterize a material at a long distance (1 km). Signatures from a given material are useful to identify the material that is targeted from at a given distant point. For instance, Figures 1 and 2 show the spectroscopic signatures for two different types of glass. Many more materials are being investigated in our laboratory to develop and apply distance spectroscopy for various materials. Figure 3 is showing how samples are mounted during the investigation.

1b. Heating at constant temperature using near or mid-infrared laser

Heating of a water-based substance or bones can improve healing in particular medical applications, such as osteoporosis or the fabrication of implants. Maintaining biological tissue or bones at a constant temperature or within a very small temperature margin may also accelerate treatment in the case of photo-dynamic therapy. Figure 4 is showing that water (5ml) can be controlled to a constant temperature without excessive swings during nearly 2 minutes. After raising the water sample to a temperature of 60ºC using CO2 laser pulses at a repetition rate of 5 kHz and then switching to a faster repetition rate of 20 kHz, the sample temperature is maintained constant. The period at which temperature is maintained constant is shown in Figure 4 between the two dash lines. Porcine bone samples were also maintained at constant temperature using the same method just described previously.

1c. Temperature auto-correction at constant temperature by far-infrared lasers

Methods are being developed now to maintain of a material at a constant temperature by detecting the rate of heating and change the laser power in real-time during a given procedure. This method will reduce the overshoot in temperature at the outset of a procedure before the sample reach a constant temperature (see figure 4).

2. Fiber micro-machining using CO2 laser

2a. Fibre optic platforms structures

Micromachining of holes into the core of a conventional fiber is attempted to hold a fluorescing substance to be analyzed. As optical fibers are easy to connect to standard equipment for quick spectroscopy sensing, they are used as a platform. Figure 5, summarizes the idea. A small conical hole of about 40 µm in diameter is drilled by laser into the core of a conventional SMF 28 of 125 µm. Then a liquid to be diagnosed can be inserted into the micro-machined hole. Light can be launched at one end (left end in figure 5) and then it becomes possible to detect the fluorescence at the other end (right end).

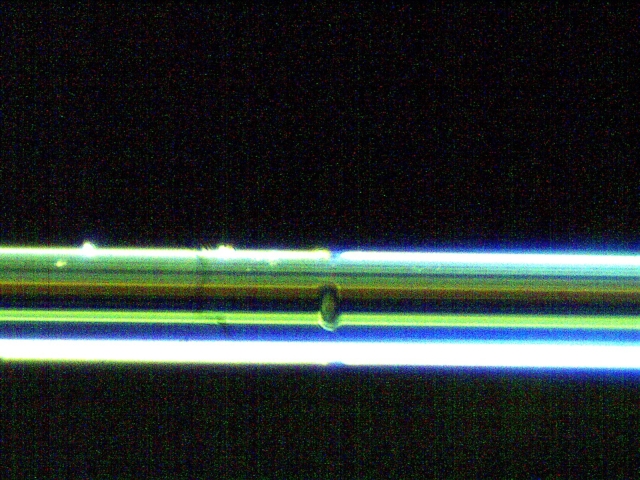

2b. Surface nanoscale axial photonics (SNAP)

The work previously done on the conventional optical fiber is opening some possible resonator to be built such as the bottle resonator. Such bottle resonator can be produced by rotation of the optical fiber through the axis at low power to melt the cladding locally.

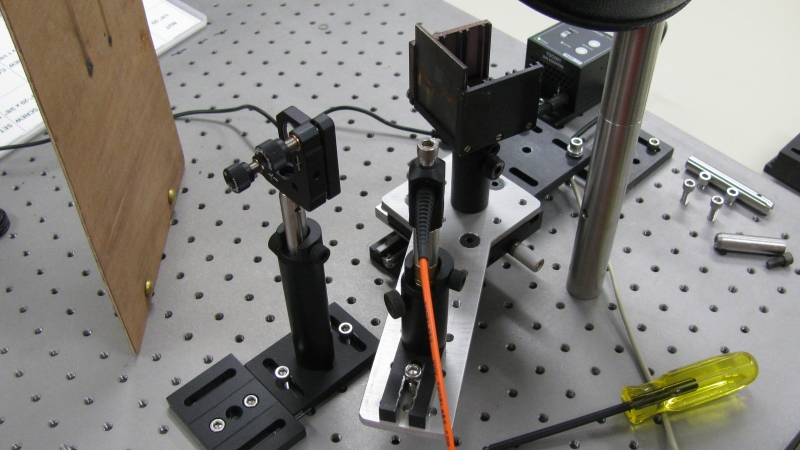

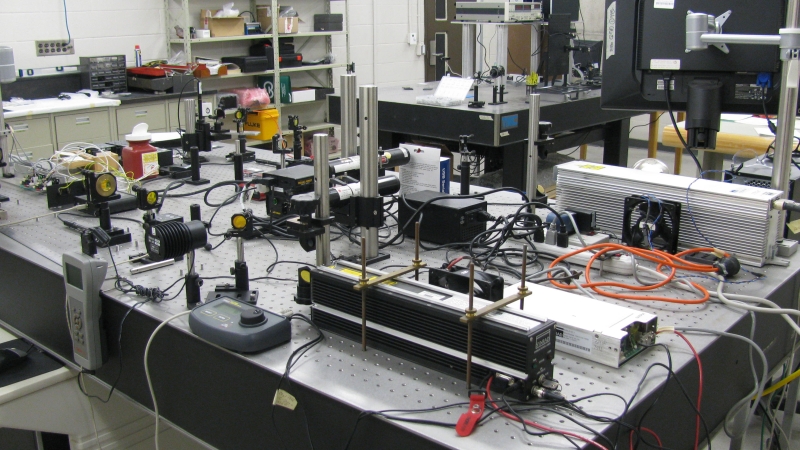

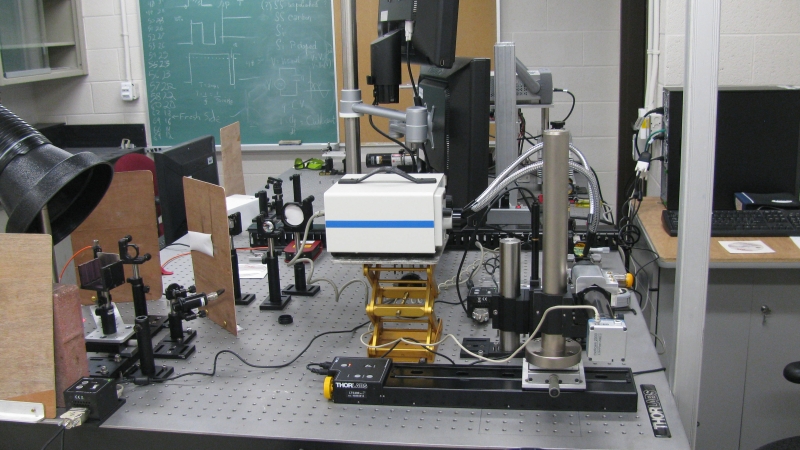

Here are some pictures of the set-up on the optical tables in my labs.

Papers Published or Presented at Conferences Recently

- L. Lévesque, Jean-Marc Noël, and Calum Scott. Controlling the temperature of bones using pulsed CO2 lasers: observations and mathematical modeling, Vol. 6, Issue 12, pp. 4768-4780 (2015).

- L.Lévesque, Nyquist sampling theorem : understanding the illusion of the spinning wheel pictured with a video camera, Physics Education 49(6) pp 697-705 (2014).

- L. Lévesque, Law of cooling, heat conduction and Stefan-Boltzmann radiation laws fitted to experimental data for bones irradiated by CO2 laser, Biomedical Optics Express, Vol. 5, Issue 3, pp. 701-712 (2014).

- L. Lévesque, Temperature control of water-based substances by CO2 laser for medical applications, Applied Optics, Vol. 52, Issue 16, pp. 3856-3863 (2013).

- L. Lévesque, Reflection, Transmission and Diffraction Efficiencies in Homogeneous Optical Thin Film and Grating Structures: An Overview, Applied Physics Research; Vol. 5, No. 5, pp. 1-20 (2013).

- L. Lévesque, Transfer function of multi-stage active filter: A solution based on Pascal’s triangle, Eur. J. Phys., Vol. 33, Issue 1, pp. 55-63 (2012).

- L. Lévesque and R.G. Sabat, Thermal lensing investigation on bulk ceramics and thin-film PLZT using visible and far-infrared laser beams, Opt. Mat., 33, pp. 460-465 (2011).

- L. Lévesque and V. Jdanov, CO2 laser ablation of bent optical fibers for sensing applications, J. Opt. 13, (IOP Publishing), pp. 1-6 (2011).

- L. Lévesque, Determination of thickness and optical constants of metal films from an extended ATR spectrum by using a statistical method, Optics & Laser Technology, 43, pp. 14-19 (2011).

- L. Lévesque, V. Jdanov, Optical fiber cleaved at an angle by CO2 laser ablation: Application to micromachining. Optics & Laser Technology 42, pp. 1080-1083 (2010).

- L. Lévesque, Close up of monochromatic aberration using Snell’s law: an undergraduate computational experiment, Eur. J. of Phys. (IOP Publishing), 30, pp. 1201-1215 (2009).

- L. Lévesque, Divergence of far-infrared laser beam and collimation for Galilean and Keplerian system designs, Optics & Laser Technology, 41, pp. 557-561 (2009).

- L. Lévesque, Simple smoothing technique to reduce data scattering in Physics experiments, Eur. J. Phys. (IOP), 29,155-162, 2008.

- P.L. Rochon and Luc Lévesque, Standing wave surface Plasmon mediated forward and backward scattering, Opt. Express, 14, 13050-13055 (2006).

- P. Rochon, L. Levesque. Multiple surface gratings on azopolymers for generating surface plasmons. Photonics North, Quebec City, Quebec, June 2006.

- L. Lévesque, P.Rochon. Controlling the photonic bandgap by surface relief azopolymer films sputtered with gold. Canadian Association of Physicists Congress, Brock University, St. Catherine, Ontario, June 2006.

- L. Lévesque, P.Rochon. Surface plasmon photonic band gap in azopolymer gratings sputtered with gold. JOSA A 22, 2564-2568 (2005).

- L. Lévesque. Revisiting the coupled-mass system and analogy with a simple band gap structure. European Journal of Physics (IOP), 27,133-145 (2006).

- A. Cournoyer, M. Levesque, L.Lévesque. Method for engraving materials using laser etched v-grooves. US Patent no. 7,023,001 (2006).

- P. Rochon, L. Levesque. The use of relief gratings to control and observe surface plasmon propagation. Canadian Association of Physicists Congress, Vancouver, British Columbia, June 2005.

- A. Cournoyer, L.Lévesque, M.Levesque, Sub-spot size CO2 laser micromachining of features in fused silica by V-groove etching, SPIE 5578D, Photonics North, Ottawa, 5578-72, Sept. 2004.

- A. Cournoyer, D. Antonov, L.Lévesque, D. Cantin, M. Levesque, Laser drilling and routing in optical fibers and tapered micro-pipettes using excimer, femtosecond and CO2 lasers, SPIE 5578D, Photonics North, Ottawa, 5578-79, Sept. 2004.

- M.Levesque, A.Cournoyer, L.Lévesque, CO2 laser processing of optical fibers, Proceedings of the 23rd International Congress on Applications of Lasers and Electro-Optics 2004.

- L.Lévesque, Revisiting the Nyquist Criterion and Aliasing in Data Analysis, Eur. J. Phys. 22 (2001), 127-132.

Books or book chapters

- L. Lévesque, Distance Education Course at Laurentian University: Uses of Lasers and Fibers Optics in Medical Sciences (2000). Manual revised 2010.

- L. Lévesque, Propagation of Electromagnetic Waves in Thin Dielectric and Metallic Films (22 pages), Chapter 12 in Electromagnetic Waves in March 2011, Book 1 (INTECH), ISBN 978-953-307-568-6, Edited by Prof. Vitaliy Zhurbenko.

Comments

Comments or suggestions are welcomed at: bryce.bennett@rmc-cmr.ca